Upstream & Downstream Analysis

Customer Challenges

Company wanted to use advanced analytics techniques to:

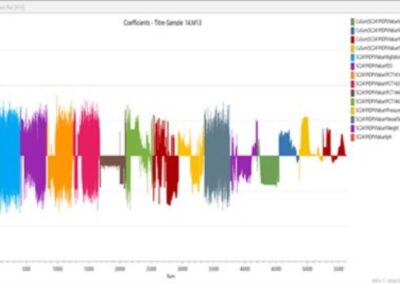

Complete multivariate analysis on Upstream Bio Reactor and downstream chromatography data

Complete Coefficient variability analysis to find key contributing model inputs

Rank key process variables

Modelling of best fit / golden batches to determine the scale of process variability

Provide recommendations for reduced variability of Titre & protein extraction levels

Solution

Phase 1 – Downstream analysis covering:

15 days professional service engagement over 3 months

Extraction of Chromatography and Cross Filtration data from Cytiva AKTA and UNIFLUX systems via UNICORN

Analysis of data to assess stability, controllability and predictability of downstream processing using TIBCO Spotfire and Sartorius SIMCA

Phase 2 – Upstream analysis covering:

30 days professional service engagement over 3 months

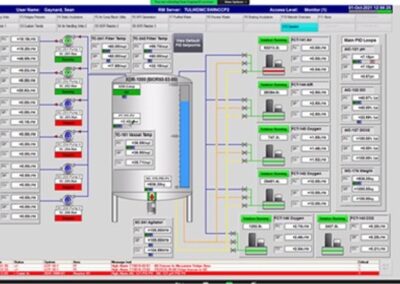

Extraction of SCADA data from CYTIVA Xcellerex / AVEVA (Wonderware), combined with Offline and Harvest data

Custom pre-processing code written to process 3,000+ extracted data files for 20 batches & prep for multi-variate analysis

Analysis of data to assess stability, controllability and predictability of Upstream processing using MATLAB and Sartorius SIMCA

Benefits

Identification of factors effecting quality & hypothesis for further manufacturing optimisation.

Related Case Studies

Food Industry

The client needed to augment their business intelligence team as they looked to update their existing Power BI / Tabular business intelligence architecture to a Power BI / Fabric environment.

Healthcare

Clarke Analytics completed an AS-IS and TO-BE analysis across a few key customer lifecycle processes to identify possible areas for improvement.

Pharma

8-week professional service engagement,

Data Analytics Maturity Assessment, interview with all key business units & IT data governors.

Let's explore the art of the possible